What is a solenoid?

A solenoid is an electromechanical device that converts electrical energy into mechanical work. It consists of a coil of wire wound around a cylindrical core made of ferromagnetic material. When an electric current flows through the coil, it generates a magnetic field that moves an armature inside the coil. This movement can be used to control mechanical systems, such as valves, locks, or relays.

Solenoids come in various types, including linear solenoids, which produce straight-line motion, and rotary solenoids, which generate rotational movement. They are commonly used in industrial automation, automotive applications, medical devices, and consumer electronics.

Solenoids operate on direct current (DC) or alternating current (AC) and can be designed for either push or pull actions. Their advantages include fast response times, reliability, and precise control. Due to their simple design and efficiency, solenoids are widely used in applications requiring controlled mechanical motion.

Types of solenoid

Solenoids can be divided into several main types, based upon their movement type and function:

Linear Solenoids

A linear solenoid is an electromechanical device that converts electrical energy into linear motion, making them ideal for automation, locking mechanisms, and industrial applications. It consists of a coil of wire wound around a metal housing, with a movable armature (also known as a plunger) at its core. When an electrical current passes through the coil, it generates a magnetic field, pulling or pushing the armature in a straight line.

Linear solenoids come in two main types: pull-type (where the armature retracts when energised) and push-type (where the armature extends, generally via a pushrod). Some solenoids incorporate a spring return mechanism, ensuring the armature moves back when power is removed.

Commonly used in locking systems, automation, medical devices, and industrial machinery, linear solenoids offer fast response times, durability, and precise control. They typically operate on DC voltage (with 12 or 24V coil windings being the most common) and can be designed for continuous or intermittent duty cycles.

Advantages of linear solenoids include compact design, high reliability, and maintenance-free operation. With customisable force, stroke length, and mounting options, they are versatile solutions for motion control. Whether used in electric locks, valves, robotics, or automotive systems, linear solenoids provide efficient and controlled actuation for various applications.

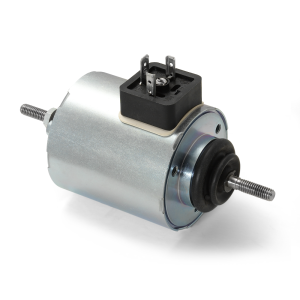

Please see below for examples of Magnet Schultz Linear Solenoids:

Rotary Solenoids

A rotary solenoid is an electromechanical device that converts electrical energy into rotational motion, making it ideal for applications requiring fast, precise, and controlled angular movement. Unlike a linear solenoid, which moves in a straight line, a rotary solenoid rotates a shaft or armature when energized.

Rotary solenoids typically use a helical or ball race mechanism to convert axial motion into rotational movement. When current flows through the solenoid coil, it generates a magnetic field that pulls or pushes the armature, causing it to rotate. The rotation angle can vary, typically between 25° and 110°, depending on the design. Some models include spring return mechanisms, ensuring the solenoid returns to its original position when power is removed.

These solenoids are widely used in locking systems, robotics, medical equipment, vending machines, and industrial automation. They offer high torque, rapid response times, and compact designs, making them suitable for space-constrained applications.

Available in DC voltage options (such as 12V or 24V), rotary solenoids are designed for continuous or intermittent operation. With their high durability, maintenance-free operation, and precise actuation, they provide a reliable solution for controlled rotary movement in demanding environments.

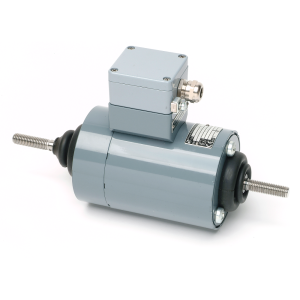

Please see below for examples of Magnet Schultz Rotary Solenoids:

Electromagnets

An electromagnet is a magnetic device that generates a magnetic field when an electric current flows through a coil wound around a ferromagnetic core. The strength of the field depends on the amount of current applied. Once the power is removed, the magnetic field disappears. Electromagnets are widely used in relays, solenoids, magnetic locks, lifting systems, and industrial automation due to their ability to switch on and off instantly. However, they require continuous power to maintain their magnetic force, leading to energy consumption and potential heat buildup.

An electropermanent magnet, on the other hand, combines a permanent magnet and an electromagnet to create a controllable magnetic field without continuous power. Magnetic holding force is provided by the permanent magnet, which is surrounded by a tightly wound coil. When energised, the current flowing through the coil induces an opposing magnetic field, cancelling out the force exhibited by the permanent magnet. This makes electropermanent magnets highly energy-efficient, as they retain their hold even if power is lost.

Electropermanent magnets are commonly used in workholding, industrial lifting, and robotics, where strong holding force with minimal power consumption is needed. Compared to electromagnets, they offer greater thermal stability and energy efficiency, making them ideal for applications requiring secure magnetic control.

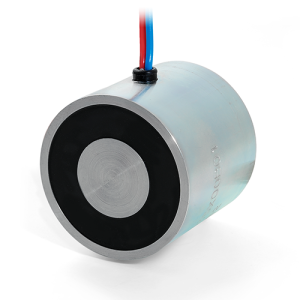

Please see below for examples of Magnet Schultz Electro- and Electropermanent Magnets:

Shotbolts

A shotbolt (or shootbolt) is a locking mechanism that uses a sturdy bolt to secure doors, gates, or machinery by sliding into a corresponding housing or strike plate.

Solenoid-driven shotbolts utilise a linear solenoid to control the movement of a bolt; when powered, the solenoid generates a magnetic field that pulls or pushes the bolt, locking or unlocking a door, gate, or mechanical system. These shotbolts are commonly used in access control, industrial machinery, and automation systems where remote or automated locking is required. They provide fast and reliable operation with minimal mechanical wear. Often integrated with electronic security systems, shotbolts enhance safety by ensuring secure locking and controlled access, making them ideal for high-security and precision applications.

Please see below for examples of Magnet Schultz Shotbolts: