Penguin

Beer & Wine is Safe for Aston Martin Boat Owners

Luxury British sports car marque, Aston Martin, has extended its brand influence with a new performance power boat. The 37-foot craft sporting the Aston Martin name is built to the same exacting standards as the company’s celebrated cars. Owners can even choose to have their AM37 craft built to match the colour of their Aston Martin car, albeit with paint manufactured to marine-grade specifications for quality and durability.

Among the many luxuries you would naturally expect from this high-profile brand is an innovative refrigerator on board the AM37 to keep beers and wines at the perfect temperature. But with these sea-going craft capable of making 50 knots (over 56mph), the physical security of the owner’s stock of liquid refreshment is equally important. That’s why Aston Martin’s boat builder, Quintessence Yachts of Southampton, turned to the marine and vehicle refrigeration specialists at Havant-based Penguin. In turn, Penguin partnered with electromagnetic actuator experts Magnet Schultz Ltd to develop bespoke electric fridge locking mechanisms to meet some very special design criteria.

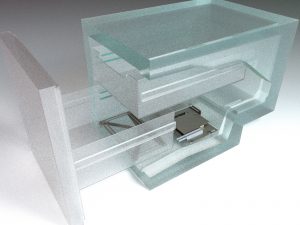

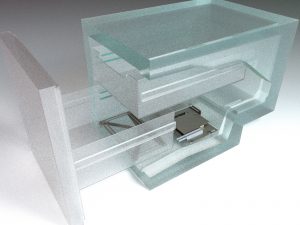

Rather than a conventional fridge with a door, Gorringe and his team conceived an elegant unit based on a pair of slide-out refrigerated drawers. This gave the unit a contemporary edge, lending itself to styling without a handle that suits the impressive craft interior, and simplified the way in which bottles and tins are held securely within. In addition, the unit was to be remotely lockable without the need for human intervention when the craft is underway.

In its initial design, to prove the concept, the Penguin team deployed an electromagnet to secure each drawer. Gorringe contacted solenoid and electromagnetic mechanisms specialist Magnet Schultz Ltd (MSL) who supplied a sample energise-to-release electro-permanent magnet. “Upon testing, small delays in the magnetic actuation profile rendered the design unreliable, so we abandoned that and sought a better solution,” explains Gorringe. “We contacted MSL again, where their designers said they could do it.”

The Surrey-based company offers a unique design service that draws on its 40-years of solenoid actuation expertise to take concepts through to engineered prototypes, via testing and design refinements to manufacture. Andrew Newton, Managing Director at Magnet Schultz Ltd, describes the challenge for his engineering team: “We offered to develop a special drawer locking mechanism for Penguin, and to undertake that prototype development process without charge. We saw a broader potential market for the resulting product in other superyacht applications. And besides, this kind of innovation – working to a minimal brief to create a bespoke product with wider uses – is at the core of our business.”

Informed by the outcome of the initial test prototype, MSL engineers set about refining the design to make the lock more robust and capable of surviving the harsh conditions. The final development phase benefited from the sea test result as well as clearly identified requirements for some features, including those designed to add a bit of cool: “The soft-open function added an extra dimension to our development challenge, but is an impressive and elegant feature,” Newton explains. In addition, aspects of the final application dictated certain product characteristics: marine-grade construction was imperative as was resistance to chemical clean down. The lock needed to be suitable for different sized drawers. And the electric push-button operation needed a manual override in case of power failure. The project was successful.

The first two production lock units were delivered and fitted to Penguin fridges in AM37 power boats. These craft are now in the hands of their owners. To date, there are no reports of issues, concerns or failures of the impressive drawer fridge, its electric lock, or its rather cool soft-open function – a blue LED array illuminates the fridge contents as the button is pressed. So the preservation of beers and wines at sea, and at speed, seems comfortably assured, thanks to a unique collaboration between two specialist British engineering companies.