Electromagnets for Target Drone Recovery Systems

Reliable electromagnetic solutions for global leader in drone target systems.

Target drones are essential tools for military training and weapons testing, simulating real-world aerial threats in controlled environments. To ensure safety, reduce operational costs, and capture valuable training data, these UAVs must be recovered intact when not destroyed during live-fire exercises. However, developing a drone recovery system that is robust, repeatable, and cost effective presents a significant engineering challenge.

This case study explores how Magnet Schultz Ltd partnered with a global leader in unmanned air, sea, and land target systems to deliver a highly reliable electromagnetic solution for parachute release mechanisms in target drones.

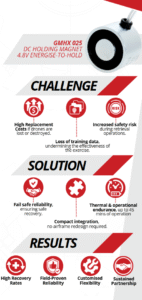

For defence organisations, target drones play a critical role in live-fire training exercises. When these UAVs survive a mission, they must be safely recovered. Without a reliable recovery system, operators face high replacement costs if drones are lost or destroyed, loss of training data, undermining the effectiveness of the exercise and increased safety risks during retrieval operations. The client required a parachute release mechanism that could withstand high G-forces during drone launch, repeated arming and disarming cycles, and exposure to harsh operating environments – all while remaining compact and cost-efficient for large-scale deployment across their target drone fleet.

The Solution

To meet the demanding requirements of a robust and repeatable recovery system, Magnet Schultz collaborated closely with the customer’s engineering team to adapt one of its proven electromagnetic technologies into a fully integrated parachute release assembly. Rather than a simple off-the-shelf component, the final design featured several key modifications to ensure seamless fit, function, and reliability within the drone’s architecture:

- Counter-bored armature design – precision-machined to accommodate a spring-loaded ball and detent arrangement, providing secure mechanical locking during flight and controlled release when triggered. This ensured the parachute remained safely restrained under high G-forces yet released cleanly when commanded.

- Custom wiring loom integration – developed to simplify installation within the drone’s confined airframe and minimise assembly time. The harness included bespoke connectors and strain-relief features to ensure reliable operation under vibration and temperature extremes.

- Compact mechanical adaptation – by tailoring the housing geometry and mounting interface, the electromagnet assembly could be integrated directly into the existing airframe.

- Operational endurance testing – the adapted design was validated across repeated arming and deployment cycles to confirm consistent performance under realistic launch and recovery conditions.

This tailored approach transformed standard electromagnet technology into a specialised, flight-ready subsystem, balancing mechanical robustness, reliability, and ease of integration while maintaining cost efficiency for fleet-wide deployment.

Results Achieved

By engineering around the customer’s platform rather than asking them to adapt to the component, Magnet Schultz delivered a cost-effective, flight-proven recovery solution that continues to support reliable UAV operations in demanding defence environments.

- Seamless Integration – the customised armature and wiring loom design enabled drop-in installation across multiple drone platforms, eliminating the need for costly airframe modifications.

- High Recovery Success Rate – consistent and repeatable parachute deployment ensured safe UAV recovery, significantly reducing replacement costs and improving training efficiency.

- Proven Reliability – extensive field testing and operational use demonstrated exceptional durability, with zero electromagnet-related failures reported across thousands of deployment cycles.

- Design Adaptability – flexible connector and voltage options and mechanical interface variants allowed the same core solution to be adapted for diverse drone models worldwide.

- Enduring Partnership – more than 15 years of continuous collaboration, technical support, and iterative improvements have strengthened the relationship and maintained performance through evolving customer requirements.

The GMHX 025 electromagnet from Magnet Schultz has proven to be a mission-critical component in target drone recovery systems, ensuring safe parachute deployment, reliable UAV recovery, and cost-effective defence training operations.